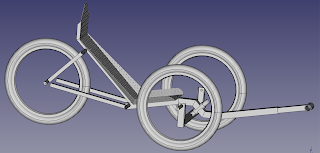

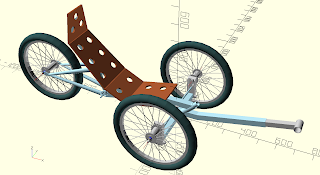

I bought a welding machine, a handyman grade, solid state, gasless MIG welder, to be precise. I already have a mini oxy-acetylene rig, too, but I've never managed to get it alight. I think the bottles may have been empty from the start. ¯\_(ツ)_/¯ Yeah, I could spend 2 grand on a KMX Kolt and get a fully functioning 1x8 speed recumbent trike with a warranty, but I think I can spend a grand all up building something similar and get 2 items crossed off the bucket list - own a trike and build some sort of bike/trike thing. Maybe it won't be as good as the KMX, maybe it'll be better. It'll be better in one way, at the very least, "I built this." Enter "Triceratops One." (That's it, up top, sitting on the baseboard for the jig I'll be building it on.) "Expense" is my main motivation. AU$2k isn't expensive as bikes and trikes go, but I'm a retiree on a "super" pension and I'd rather try and keep a bit of that cash i...