Going From 240x180x50 To 600x1200x70

I have a "toy" CNC router. It's OK for small brackets, even in aluminium... if I'm patient and keep the feed rates low and the revs on the spindle high-ish. It cost me as much "aussie" as its working X dimension, has an AnnoyTools control board, works well with OpenBuilds Control and jscut in an app wrapper does a fine job of creating 2.5D gcodes for brackets and other basic eng-ops. It's just useless for big boy shit.

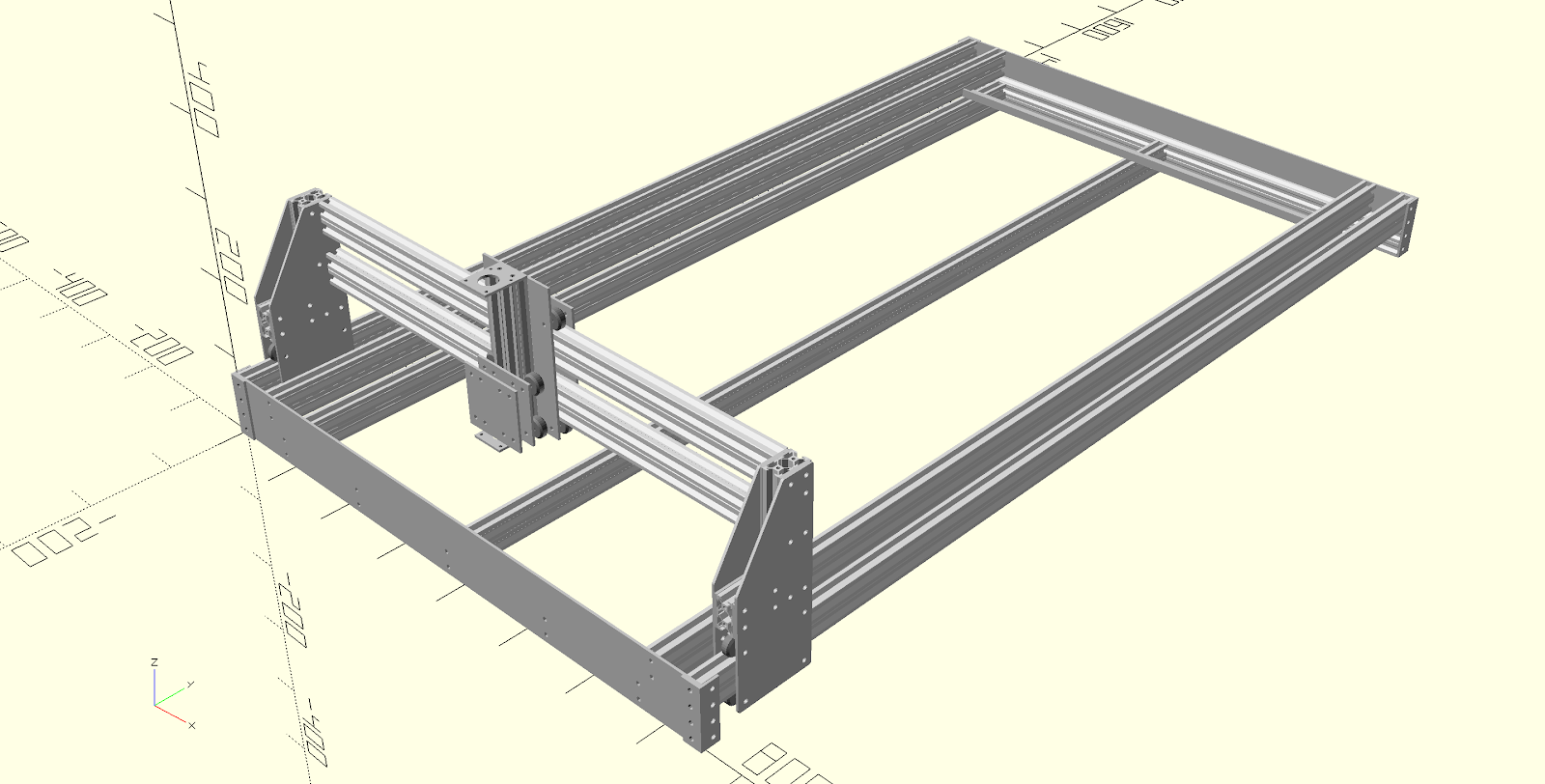

Nema17 steppers will do fine for the work I do, so they're staying. I'm not doing this stuff for money, it's a retirement hobby zone here. The spindle is an oversized slotcar motor, so I just know that will have to be replaced towards the end of the project but, until then, all I need to do is build a bigger frame. The above is it.

My local MakerStore is in Carrum and just near my railway line. They stock aluminium V-wheels, a rack-and-pinion drive system that's compatible with v-slot and the necessary V-slot extrusions. I can mill flat-brackets from 60x3 flatbar from bunnings using my drillpress and precision table. I can reuse corner brackets, hardware and motors from the mini CNC, And I have some wall space in the studio that's not infested with guitars and amplification where I can hang it when not in use. Total cost including the "toy" will still be under a grand. You can't buy a medium sized CNC from China on eBay, Ali or Crapazon for that money.

Why do this? Well, I kind of have a dream of a fretless bass guitar, made from recycled plywood, cut and laminated in a herringbone pattern, milled to a semi-hollow epiphone casino style body, but with bridge tuners, like a recycled wood steinberg clone, only not a dull, carbonfibre black. Real wood. Recycled ply, at that. Maybe a high quality tasmanian oak or river redgum through-neck. I don't really play live anymore, but a custom fretless bass was an itch I never scratched when I did play. I figure that, for a hobby crossover, that's a good itch to scratch, especially pushing the boundaries for materials, design/style and out there factor. I don't conform to the norm. I'm retired, I dunwanna, ya carnmakeme! :D

My woodwork skills are a bit rough, so automachining will give a bit more precision. It's what the tools are for.

Watch this space...

Comments

Post a Comment