Robo-Drummer Becomes "WristBot"

Like all of my projects, my robo-drummer needed unique branding. Meet WristBot, named for the drumming action I want to emulate, the "wrist-flick."

Every robot drummer project I've seen online uses a linear pull action to swing a drumstick down in a fixed arc. No rebound, no ability to motor-tweak the stick angle to extract feel from MIDI velocity, no ability on snare to raise or lower the stick height on the sidestick MIDI drum note so that both the rim and the skin are hit. Drum machines have almost as much dynamic sound control as human drummers. My Alesis SR18 does. Even the HR16 I used to use in the 80s and 90s as bassist for the Hobart, Tasmania, blues duo, Bottleneck, had feel. "Way 'too much' feel! Don't get a real drummer!" in the words of one audience member.

My aim with WristBot is to emulate that balanced stick, wrist flick grip, that allows the stick to bounce away from the skin, the instant the skin is struck. Even kick drum has "toed" and "pressed", where toed flicks the beater at the skin while pressed hits the skin then damps the hit by keeping the beater against the skin. Wrist Bot will be able to do this, too, simply delay the firmware routine that reads note-off from MIDI until Wrist Bot needs to prepare for the next "kick."

And this brings up another point - "You don't need to read note-off, MIDI is for timing musical notes, drums don't need that," writes a blogger I won't name. The MIDI standards call for note-off to even be included in drum machines, and my SR18 plays bass and percussion, it does note-off signals on all channels, including percussion and drums. If your drum machine doesn't note-off a drum beat as a formality, the engineers at the factory didn't read the MIDI standards.

So, to how Wrist Bot works. Like other robo-drum hobbyists, I'm planning to use car-door lock actuators, like this one...

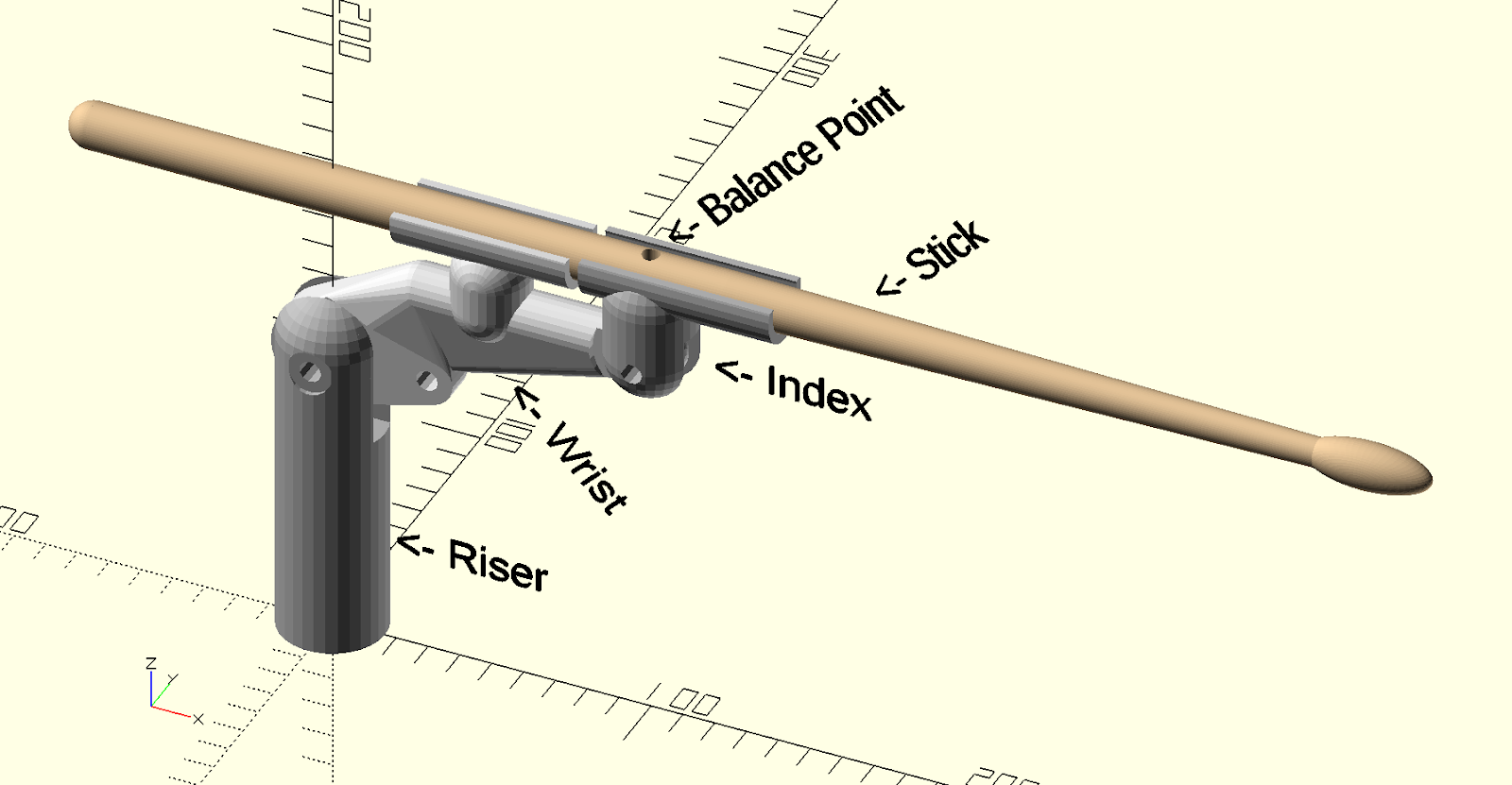

This gadget, when hit with a pulse of 12v, spins a motor which drives a pinion to push and pull a geared rack. There's 20mm of travel. Drive the motor one way, the door locks, drive it back, the door unlocks. (Yes, some use spring returns, not sure what method the test unit I've ordered uses. We'll see when it arrives.) They generate 2kg of thrust (up to 4kg) over 20mm motion, enough to break a drumstick, not enough to do a proper wrist flick with a linear pull, but that's why the motor link is close to the pivot at the top of the riser, we sacrifice some of that 2kg thrust to increase the rotation angle. This is how a human wrist works. A small contraction in the muscles attached to the heal of the hand, creates a large angle of rotation, and the finger tips can move around 150mm or more of arc length to bring a drum stick down. The stick itself pivots on the index finger, just under-balanced. A quick flick downwards casuses the stick to continue the rotation as the wrist begins to pull the hand back up, and the tip of the stick hits the drum. Then the stick rebounds and comes back to rest on the middle, ring and pinky fingers. So, the parts of Wrist Bot's parts are labelled to reflect that, the fixed stick rest (at the very top, cosest to the pivot) is called the RMP (ring, middle, pinky), the pivotinbg stick rest is the index and will have a clamp to hold the drumstick in place. The wrist itself pivots from the top of the riser, but will not travel quite far enough for the stick to hit the skin, allong the indix to finish that job, leaving the stick to have proper rebound.

This also makes replacing broken sticks easier - loosen the clamp, slide the broken stick out, slide in the new stick, tighten the clamp. All the systems I've seen require the sticks being drilled at a perfect balance point. Weakens the stick and requires a more complex disassembly to replace a brocken or worn stick.

So currently, I'm still building my secret guitar pedal for my old bandmate, Wayne. It's his idea, I'm just the guy figuring out how to make it work. That's at the stage of building a prototype for Wayne to try out and find the pedal's limitations. When I get that in the post to Tassy, and a test unit for myself built, I'll start working on Wrist Bot, but I've already ordered a few test bits and am working on the above design to 3D print a prototype for testing and calibrating. If there's one thing Arduinos do really well, it's read MIDI. If there's one thing a drum machine can do really well, it's record and play back a human feel. Having that human feel replayed into a real drum kit should create a near human drummer experience. Using Logic Pro X to drive a drummer bot with a humanoid wrist action will give that software's drummer tracks a life beyond what even Apple envisages!

Please note, I do know there is arm movement in drumming, too, but I'm not trying to build a drum android, I'm planning on having a stick or beater mechanism on each drum. Some multi-motor complexity, some single beater. It won't be an android sitting on a drum stool at real Pearl "Pictures of Lily" reissue. That is all.

ReplyDeleteActually, no it's not. This video is awesome and and this is not what I am building. This is crazy engineering, way beyond my skills. https://www.youtube.com/watch?v=9gMX_hR-RoM&ab_channel=Compressorhead

ReplyDelete