Meanwhile, Printer Dreaming

3D printers are an amazing tool and, the thing that tantalises me the most, is the potential to 3D print a 3D printer that can print its own "sister," that can print its sister, that can print its own sister...

The key to being able to print a printer that can print exact copies of itsel is only in the design and materials choice, really. These machines are only a metal printing advance away. Or are they already here? Take a look at this proof of concept.

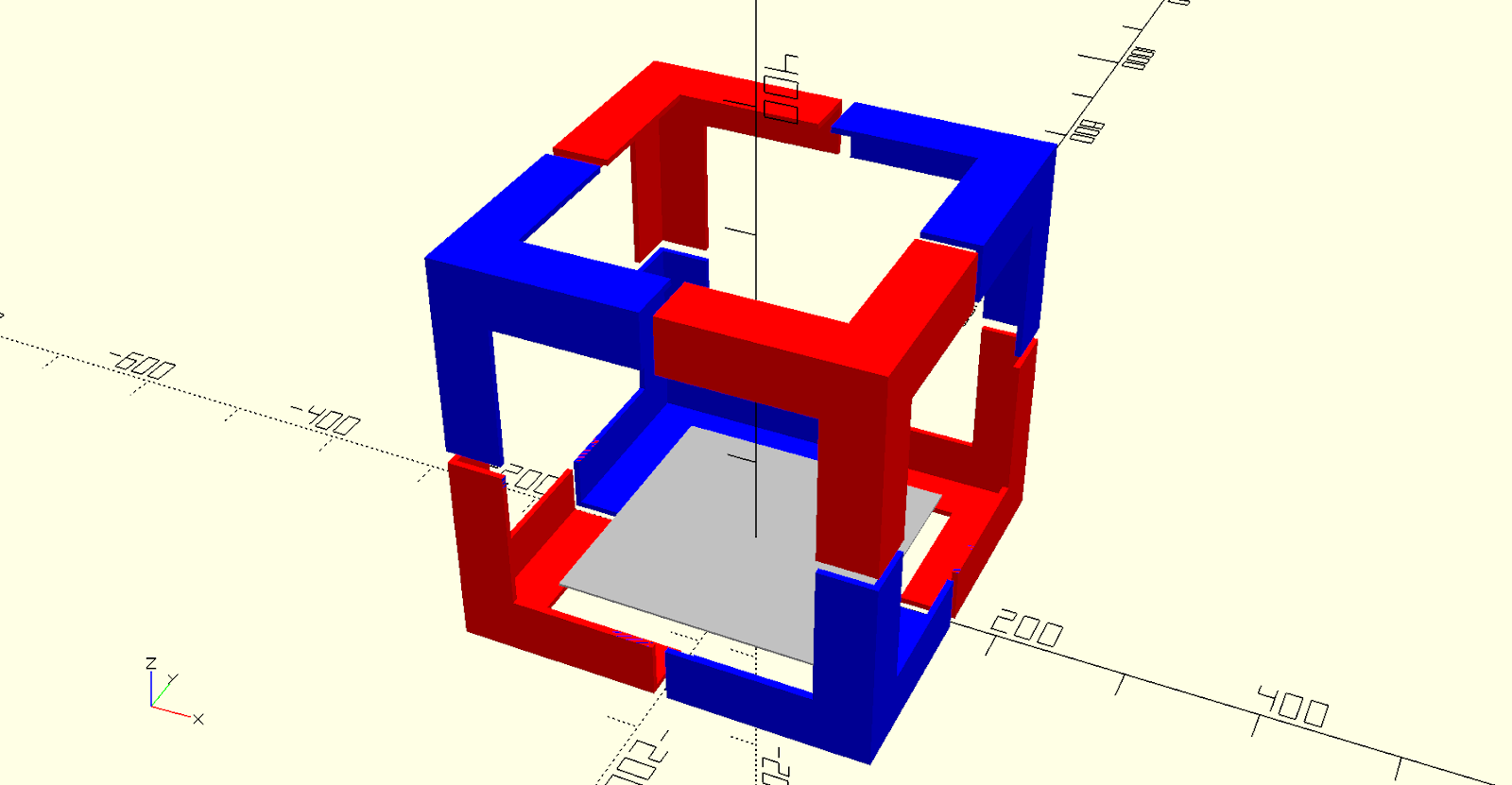

Exploded view of a concept printer with a standard 225mm x 225mm print bed that could print its plastic parts.

Exploded view of a concept printer with a standard 225mm x 225mm print bed that could print its plastic parts.OK, obviously you can't print the motors, hotend or control board. But even that might be doable if a "TIG" welder and a printer were somehow combined. We already have 3D printers that can print in 2 or more colours. It's theoretically only a small step to deposit a layer of copper on a layer of carbon-fibre impregnated PETG or nylon, even plating holes through a board and doing complex, multilayered electronics is imaginable.

So, the sketch above, shows a simple corner frame that is 160mm x 160mm x 160mm. 8 of these "corners", plus 12 joining pieces, makes the beginnings of a printer frame that can be populated with motor brackets, a core-XY printing mechanism and fixtures for wiring and electronics. That grey square in the middle is a standard 225mm x 225mm print bed. Our corners are 160x160x160 and every other part is smaller than that. The usable volume on the print bed is easily 210x210x210. This printer, when fleshed out with print files for all of the necessary structural parts, could print its "sister," and so on...

So, what are the ramifications of this? Well, it has been done before, by a German PhD student. It's not an original idea. What makes it an important idea is that it subverts at least the structural manufacturing industry. People like Creality, who make affordable, kit-form printers, may be in trouble, while people who make logic controllers for printers, like MKS are still pretty safe. We really are less than a decade from being able to print simple, 2 layer circuit boards. Put a belt-drive print bed (like the Creality CR30) inside a self printing printer design, add a pick-and-place machine at the end of that print bed, make everything printable with a copper capable hotend as well as the conventional plastic filament hotend...

Mind you, just the necessary frame corners, the blue and red bits in the sketch above, will take 10 days printing PETG-CF, 5 in PLA, but you'll still need the carbon fibre kind, for adequate strength. Then there would be brackets to join the corners, mount motors, hold lead screws... It's a big, slow job.

You know, just the same, this potentially begins to subvert industrial capitalism. If you can "print" an entire machine (maybe not the motors, but hey, the logic electronics, perhaps), have it feed a robotic assembly machine, you can assemble where and when you need the machine, then assemble what you need the machine for, then print machines for others. The only thing left for industrial processing is the raw filament. Or is it? People are already doing research, at academic as well as hobbyist levels, into recycling waste plastics as filament. There are people selling recycled PLA and PETG commercially. The breakthroughs that matter hackers need to be working on include how to place copper track securely on plastic boards.

Maybe it involves lasers. Meanwhile, I'll keep working on a printable printer housing design. One I can print in my beloved Form Futura PETG-CF on my Ender 3 Pro. Then print 2, one on the Ender, one on the PrinterPrinter, and sell one. Repeat, sell 2... repeat... repeat...

Not to mention the idea that one could, using a gasless MIG welder and "reweldable" 0.8mm wire, weld these parts in steel. Or that each generation print could be scaled up. Food for thought.

ReplyDelete